Here in 5M-IGI d.o.o., we are committed to continuous learning about new techniques/technologies and possibilities in graphic industry and it allows us to expand our services - from common prepress for different printing techniques all the way to advanced prepress services such as conversion to 7-colors printing technique (also known as Extended Color Gamut). Using precise in-house-produced color profiles, we can improve the accuracy and speed of making proofs and we are not limiting ourselves - or you - to glossy or matte paper only... Aluminium foil, various PP foils, transparent film, all those substrates are no secret to us in producing proof prints with accuracy uncompared with the usual simulation printing. Simply said, we simulate printing conditions, not the substrate!

Flexo Plate Production is our latest achievement. State of the art hardware and software combined with know-how when it comes to specific conditions and needs of any given printing plant, makes us a desirable partner for your quality improvement efforts and significantly reduce production costs.. More details below this…

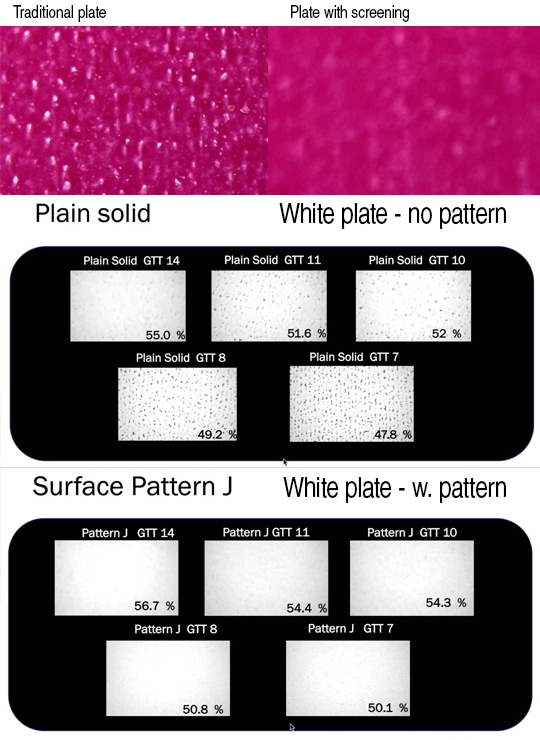

In flexo plate production we use customised plates and screenings to meet our client's needs. Beside the use of the World's latest technologies in flexo prepress (like Variable Spot Size, Clean Print, Crystal Screening, Smooth White...), our team is assembled of experts with long practical experience in flexo prepress and printing processes. Therefor, we are able to provide a high level of support to our customers when it comes to print optimisation, choosing the best anilox, adhesive tape and screening, all of which is aimed to one goal only - higher quality and expense reduction. In some cases, we managed to save 30% of ink consumption compared to production statistics before our engagement.

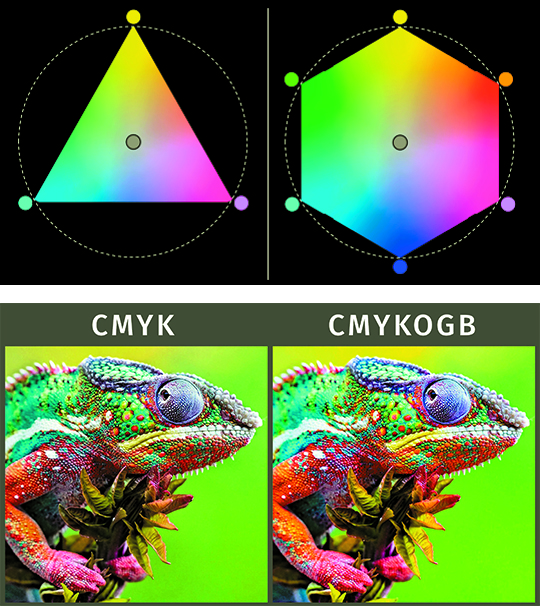

ECG stands for "Extended Color Gamut". In printing process, it means one can achieve a much bigger color space than the one with use of standard CMYK colors. ECG adds Orange, Green and Violet to standard set of colors for printing. This approach allows printers to reproduce designs by using 7 standard inks instead of CMYK plus a vast number of spot colors.

ECG gives printers a unique opportunity to significantly reduce time needed for machine preparing, ink storage and ink consumption. We can also apply ECG conversion to CMYK bitmaps (like photos) and by doing so the end result is reproduction with more vivid colors. Overall, this procedure leads to increased profitability, productivity and quality. One flexo printing machine can produce up to 200% more prints in a single shift!

There are no definite industry standards in packaging printing due to the huge spectrum of substrates, ink systems and refinement processes. If printing is done at different sites, or if different printing processes are used, minimising colour variations represents a major challenge. In the past optimisation occurred through adjustments to the printing press, but we can now safeguard the consistency of the print result through fingerprint-based targeted print colour management in the digital phase.

As a result, we work with an individual profiling process, which includes all relevant process parameters including spectral values of spot colors defined in .cxf files. This means that we can guarantee maximum color constancy from design to printing on different substrates.

All printing forms produced by 5M are carefully checked. The Step & Repeat Proof exclusively targets technical parameters. We check the distribution of use as well as the overall layout of the printing form. We also safeguard the correct placement of printing and control marks with this proof.

An image on packaging is decisive for the overall impression. Our fruits become more crispy and freshly cleaned windows gleam in the sunlight. We work with pictures produced by our photographers or with motifs supplied by outside parties. We produce a perfect shine through creative retouching and composing all in accordance with technological printing demands.

We make practical proposals on the innovative use of printing processes and create detailed technical drawings that highlight the design, colours and varnish areas for the later packaging. We offer a technical guide for agencies that summarises all the information relevant for the further prepress process as well as packaging simulations in a targeted way to correct incorrect estimates and false expectations early. The more realistically we reproduce the impression of the later packaging, the more precisely our customers can assess its impact. We simulate the later packaging with great fidelity to detail and in realistic colours with Mock-Ups. We generate both static and animated Packshots with the help of professional 3D software solutions.

We use additional software solutions, to ensure that the artwork and reproduction match exactly and on the other hand to compare repro data on a separation basis. Our software supported quality control works in a very targeted way, reliably and quickly.

In Prepress we prepare the artwork for industrial printing so that we can guarantee reliable results. By taking account of all technical parameters as far as printer-specific criteria, we can safeguard unchanging results and optimum quality.

How would your sleeve look like wrapped around the bottle? Distorted? Yes. But with our tools and 3D simulation we can reverse this effect and make it look straight and undistorted. Also, we can ensure the best positions of the elements of your design and avoid unwanted overlaps, folds or readability issues. Bottles, cups, cans, foils whatever... To make long story short, unpredictable becomes very predictable!

Feel free to contact us for more informations or request an offer.

Contact Us